Falls are the leading cause of death in the construction industry. By having a fall prevention plan in place and using the correct safety equipment, serious injuries and fatal accidents can be prevented.

Here are five ways for workers and employers to identify and prevent common fall hazards on a construction site.

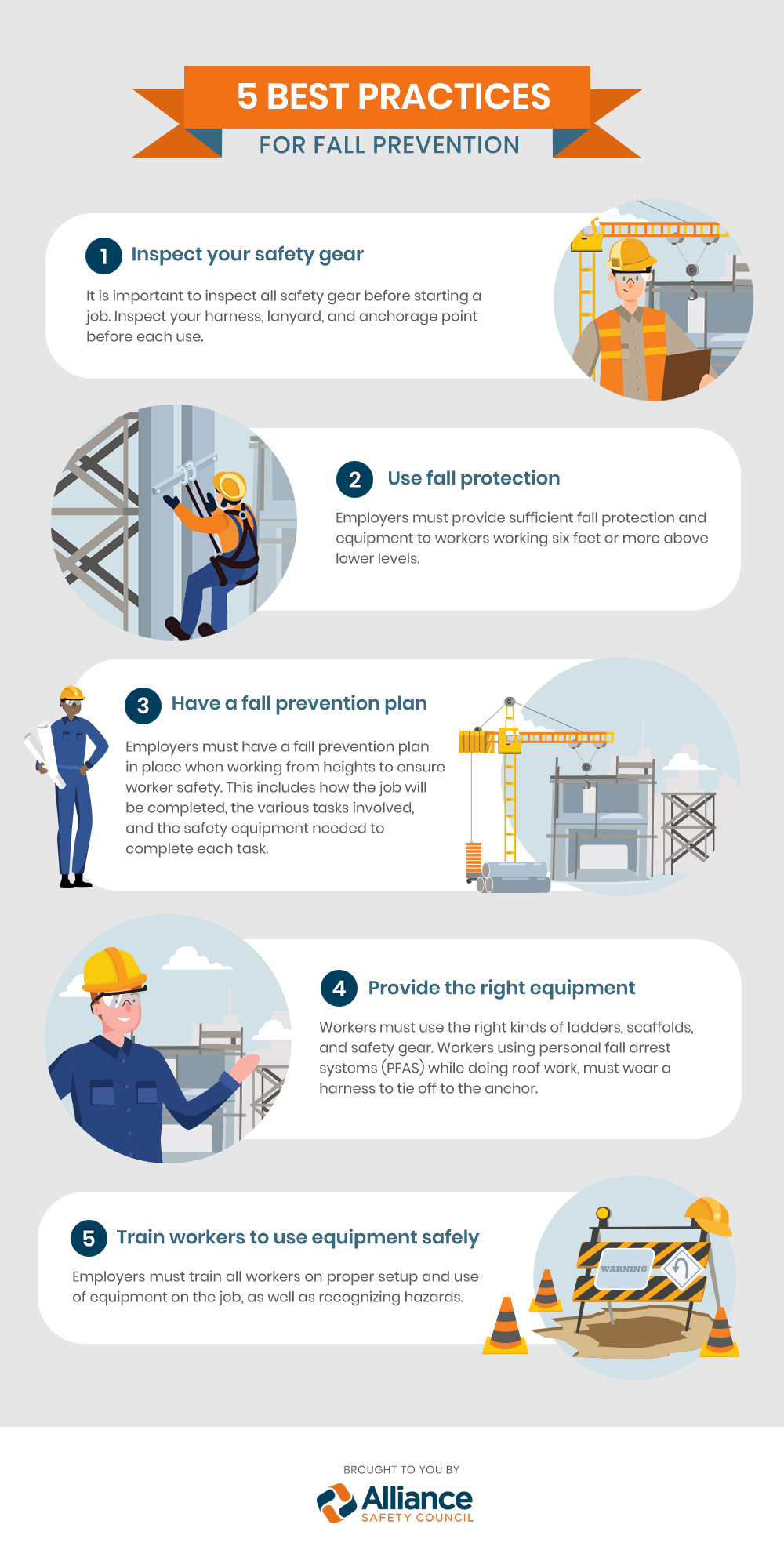

It is important to inspect all safety gear before starting a job. Inspect your harness, lanyard, and anchorage point before each use.

Employers must provide sufficient fall protection and safety equipment to workers working six feet or more above lower levels. These workers are at risk of serious injury or death if they should fall.

Employers must have a fall prevention plan in place when working from heights to ensure worker safety. This includes how the job will be completed, the various tasks involved, and the safety equipment needed to complete each task.

When estimating job costs, employers should include all the necessary safety equipment and tools, as well as a plan to have it available at the construction site.

It is important that workers use the right kinds of ladders, scaffolds, and safety gear. Workers using personal fall arrest systems (PFAS) while doing roof work must wear a harness that ties off to the anchor. The PFAS must be fitted properly and should be regularly inspected for safe use.

Employers must train all workers on proper set-up and use of equipment on the job, as well as recognizing safety hazards.

By incorporating these basic safety principles, your workers and construction site will be safer and more efficient. View our available courses section to see various courses on fall safety.

Stop falls. Save lives

Source: https://www.osha.gov/stop-falls